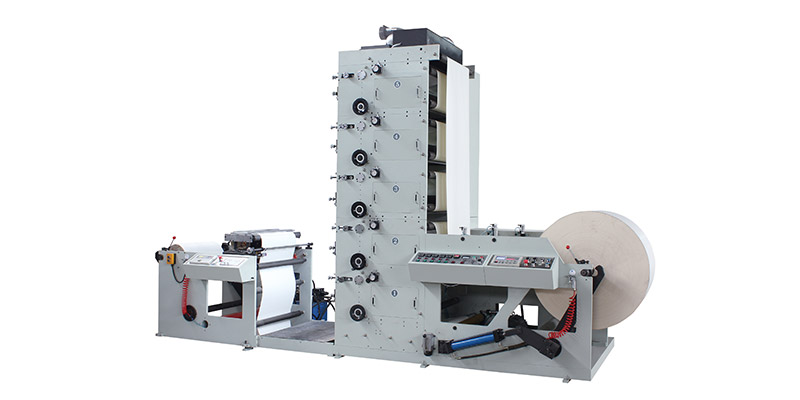

Paper Cup Flexo Printing Machine

The Paper Cup Flexo Printing Machine main motor adopts imported converter to govern in a steepless way. Feeding and discharging are controlled through magnetic powder brake and clutch .

The Paper Cup Flexo Printing Machine main motor adopts imported converter to govern in a steepless way. Feeding and discharging are controlled through magnetic powder brake and clutch .

Adopt ceramic mesh distributor roller, which is characterized by durability , wear resistance, and corrosion resistance, The doctors can be Used,Which is more efficient for reducing the times for changing in order to increase the production efficiency. The printing unit can register in 360degrees. Each printing unit can indepen deftly gear and loosen to have the units continue printing. The printing units are all equipped with a group of infrared dryers respectively. The roofing device is adopted with a group of infrared dryers respectively. The inking roller can automatically fall off at stoppage and transfer at low speed in order to keep the ink from being dry and solid. The roll feeding, printing, auto infrared drying. Laminating and rolling can be processed in one processing. Lt is characterized by wide application, non-population of printing ink and fast drying, quick printing. So it is an ideal printing machine for the commercial bill to print high Graded free adhesive trademark.

|

Printing speed |

80m/min |

|

Printing color |

5color |

|

Max web width |

960mm |

|

Max printing width |

950mm |

|

Max unwind diameter |

1200mm |

|

Max rewind diameter |

1200mm |

|

Printing girth |

250-580mm |

|

Overprint precision |

±0.1mm |

|

Power supply |

380V/AC Three-phase 50H |

|

Dimension (L*W*H) |

5250*2100*3200 |

|

Weight |

7000kgs |

Oct 28,2025

The process is a blend of traditional papermaking wisdom and modern technology, with strict steps to ensure consistency,...

Oct 13,2025

For printing factory owners, nothing is more stressful than a sudden printing machine failure. Last month, a Guangzhou-b...

Sep 25,2025

At its core, die-cutting is a manufacturing process that uses custom-shaped tools (called “dies”) to cut, score, or embo...

GET A QUOTE